Seit 1995 löten und glühen wir aus Leidenschaft. Steigende Komplexität der Bauteile und Anforderungen der Märkte sind für uns stetige Herausforderungen und Ansporn gutes noch besser zu machen.

Wir beherrschen seit 1995 die Kunst des Lötens und Glühens

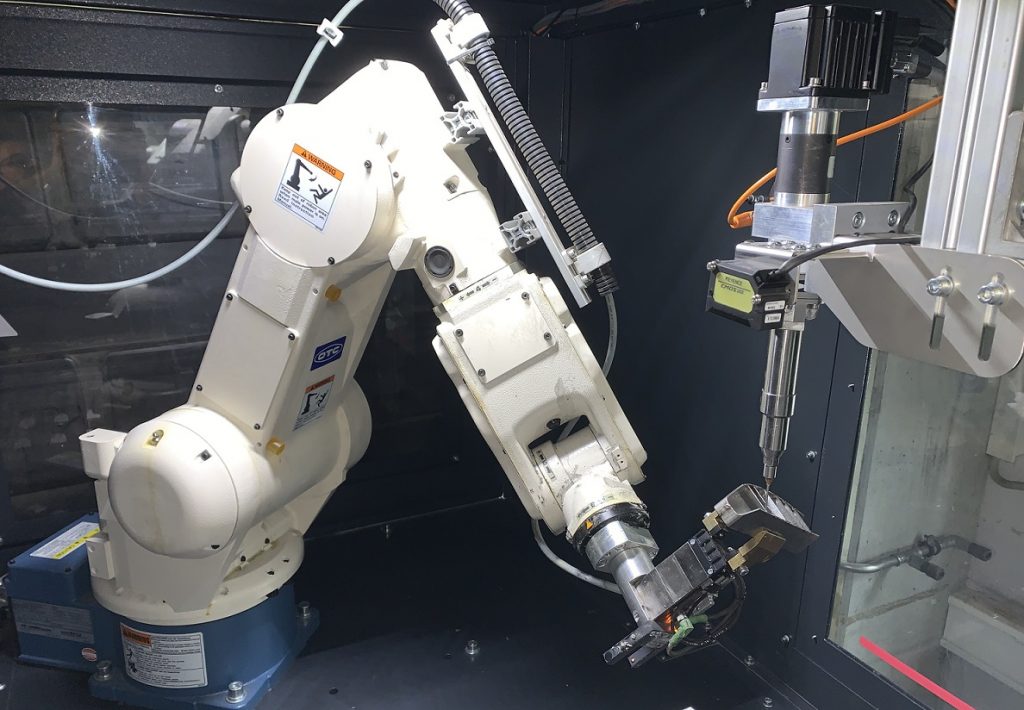

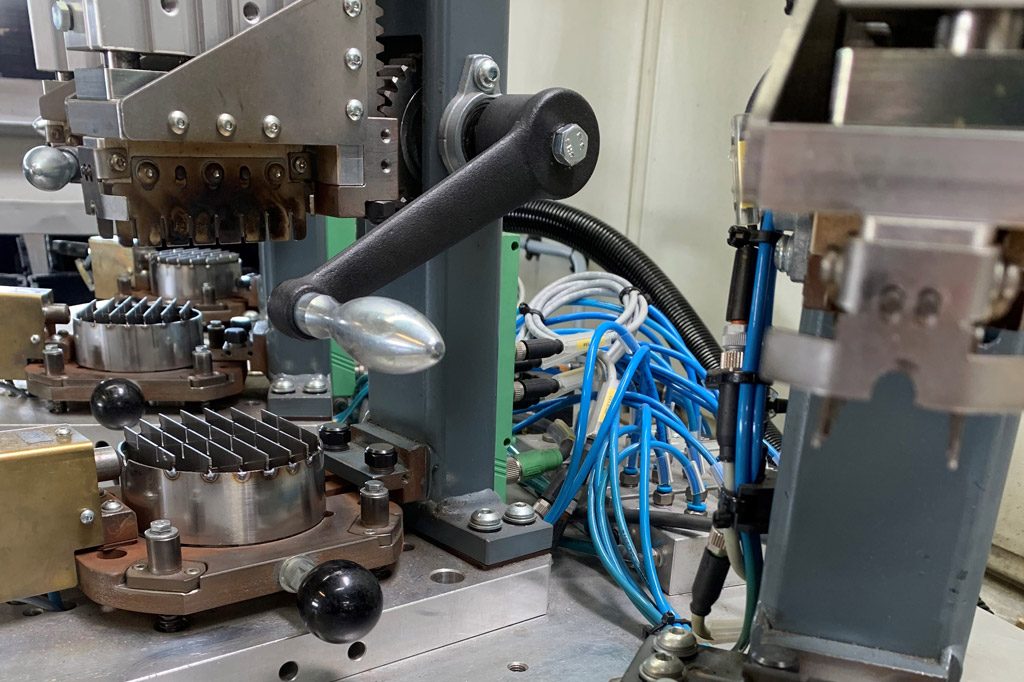

Mit dem Unternehmenszweig Löten und Glühen bieten wir Ihnen ein leistungsstarkes Unternehmen für die Wärmebehandlung von Metallbauteilen. In modernen Förderband-Durchlauf-Lötanlagen werden Bauteile aus unterschiedlichsten Metallen flussmittelfrei verlötet und/oder einer Wärmebehandlung unterzogen.

Unternehmen aus den verschiedensten Branchen schätzen unsere große Erfahrung sowie die maschinelle Ausstattung auf dem neuesten Stand der Technik.

Schätzen auch Sie unsere Flexibilität: Angefangen von maßgeschneiderten Anlagentechniken für spezielle Kundenanforderungen bis hin zum Notfallmanagement über Nacht und am Wochenende.

Lernen Sie unsere Flexibilität kennen. Wir bieten Ihnen maßgeschneiderte Fertigungsprozesse für Ihre Serienbauteile ebenso, wie Protoypenversuche und ein 24/7 Notfallmanagement.

Ihre Ansprechpartner

Löttechnik Burkhard GmbH & Co. KG

Julius-Probst-Straße 9

D-87600 Kaufbeuren

Unsere Kompetenz – Metalle ohne Aufschmelzen dauerhaft miteinander verbinden

Mit unserer langjährigen Erfahrung in der Wärmebehandlung zählen wir heute Kunden aus verschiedensten Branchen zu unserem Kundenstamm. Standard-, oder Serienfertigungen, Einzelteile oder komplexe Baugruppen – höchste Flexibilität ermöglicht dies:

- Kraftfahrzeugzulieferindustrie

- Metallbe- und -verarbeitende Industrie

- Maschinen- und Werkzeugbau

- Medizintechnik

- Armaturen- und Apparatebau

- Elektrotechnik

- Feinmechanik

- Möbelindustrie

- Sicherheits- und Verteidigungsindustrie

Unsere Leistungen

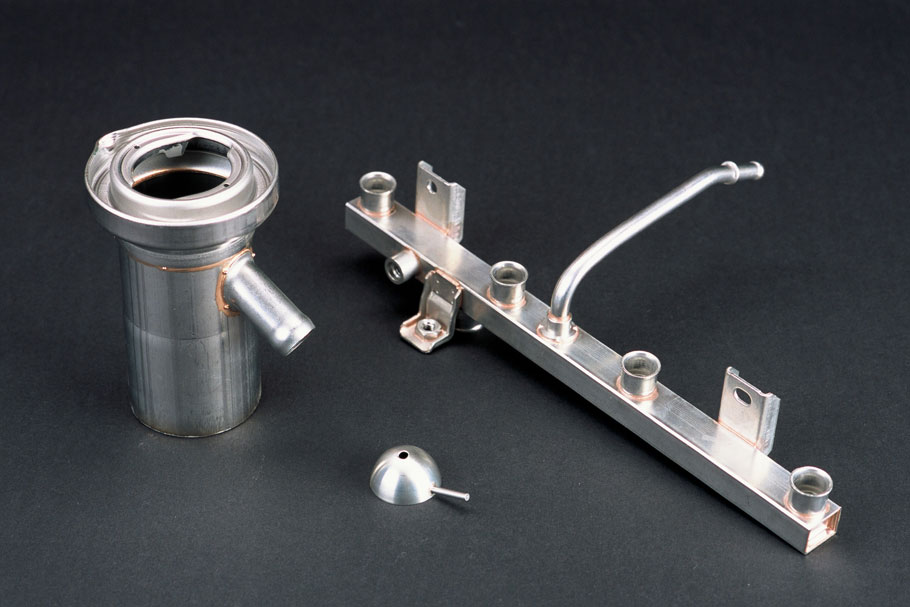

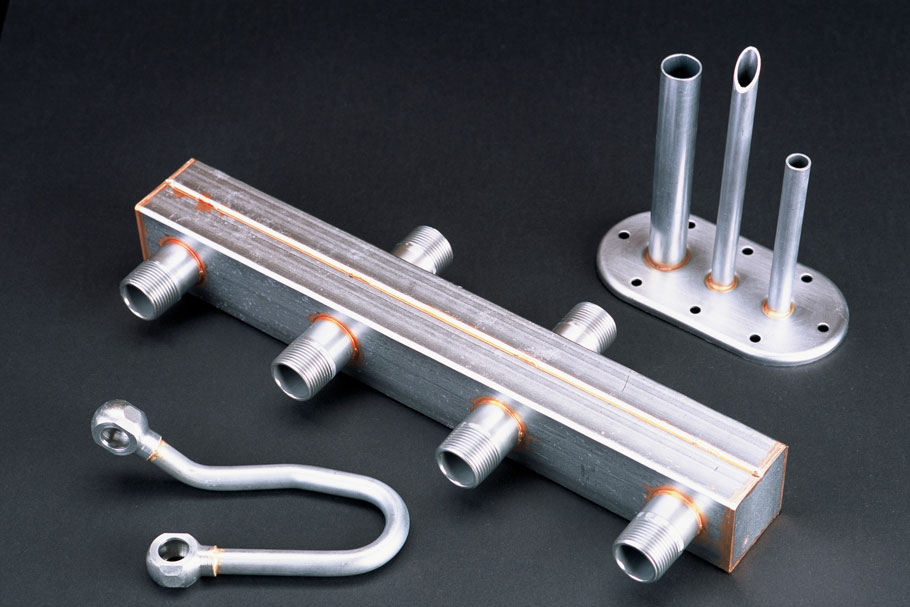

Anwendungsbeispiele

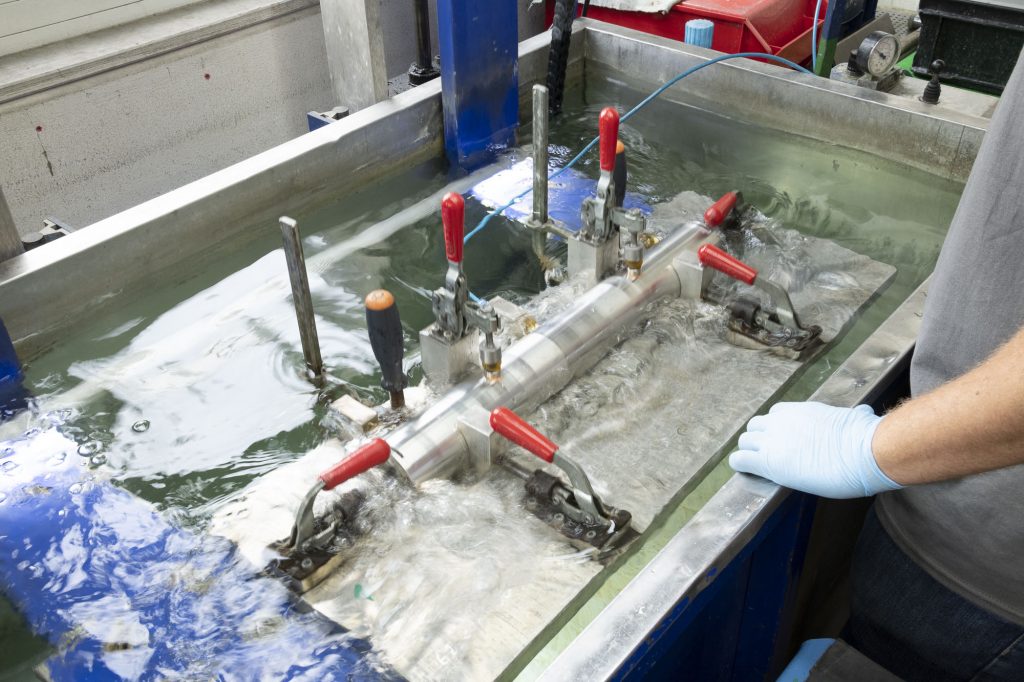

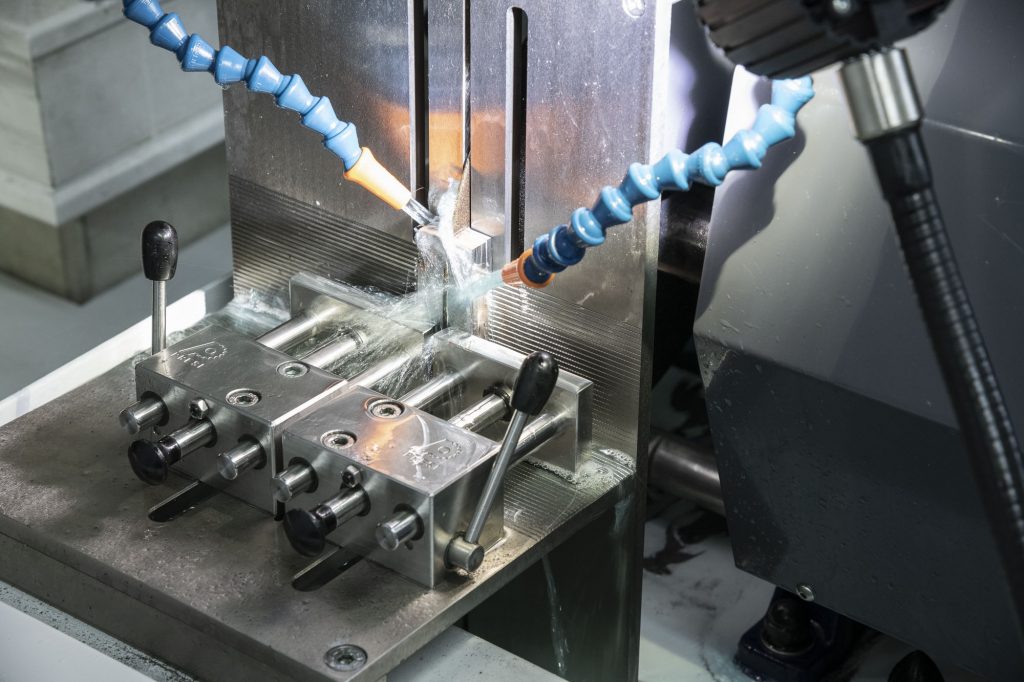

Mit Wärme Werkstoffeigenschaften ändern

Reinheit, die man nicht immer sieht: Das Aufheizen und anschließende Abkühlen von Metall unter Schutzgasatmosphäre führt zu chemisch blanken Werkstücken, frei von Zunder und Oxiden.

Das Rekristallisationsglühen kaltverformter Werkstücke ermöglicht ein weiteres Verformen. Denn anschließend ist der Werkstoff wieder spannungsarm und geschmeidig – damit erhöht sich die Standzeit des Umformwerkzeuges deutlich.

Die perfekte Basis für Ihren Umformprozess: Rekristallisationsglühen kaltverformter Werkstücke. Spannungsfrei und geschmeidig zur Schonung Ihrer Werkzeuge und Reduzierung von Mikrorissen.

Unsere Leistungen

Anwendungsbeispiele

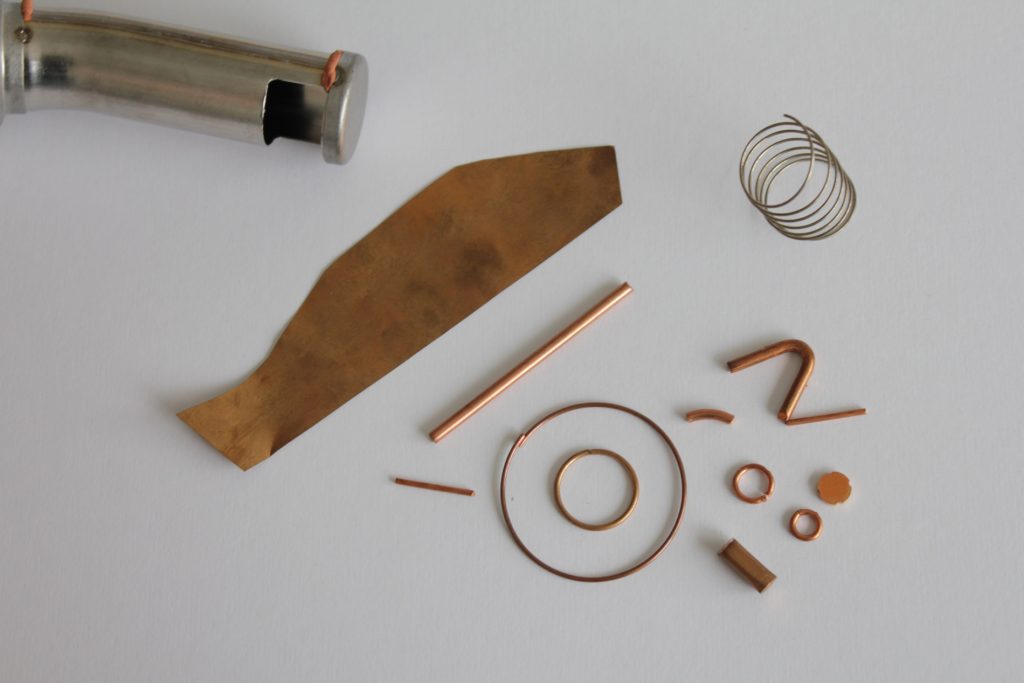

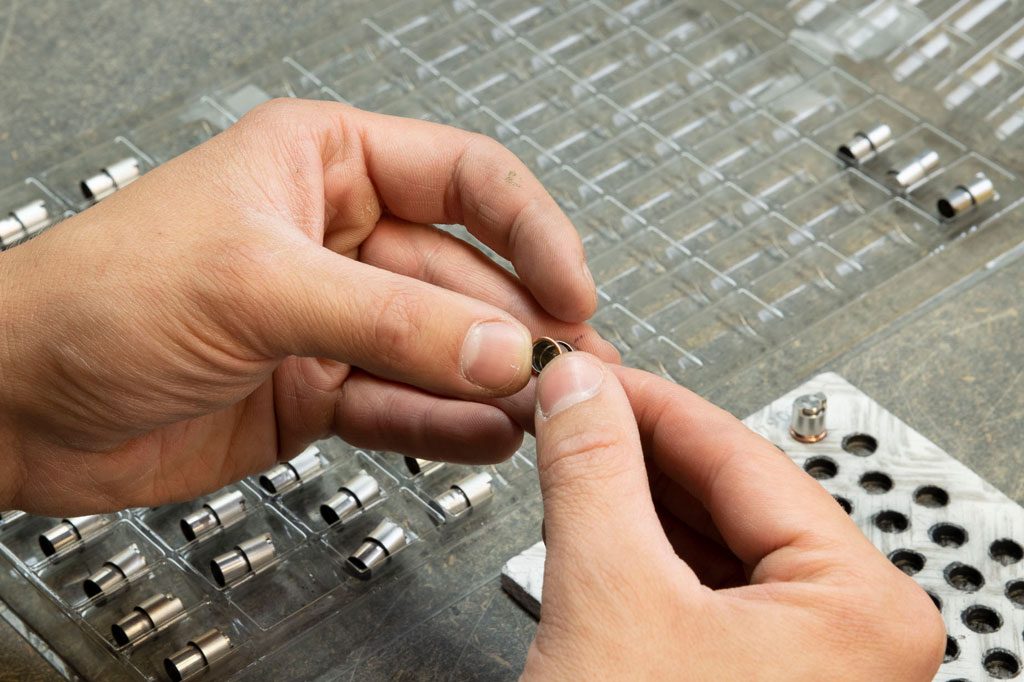

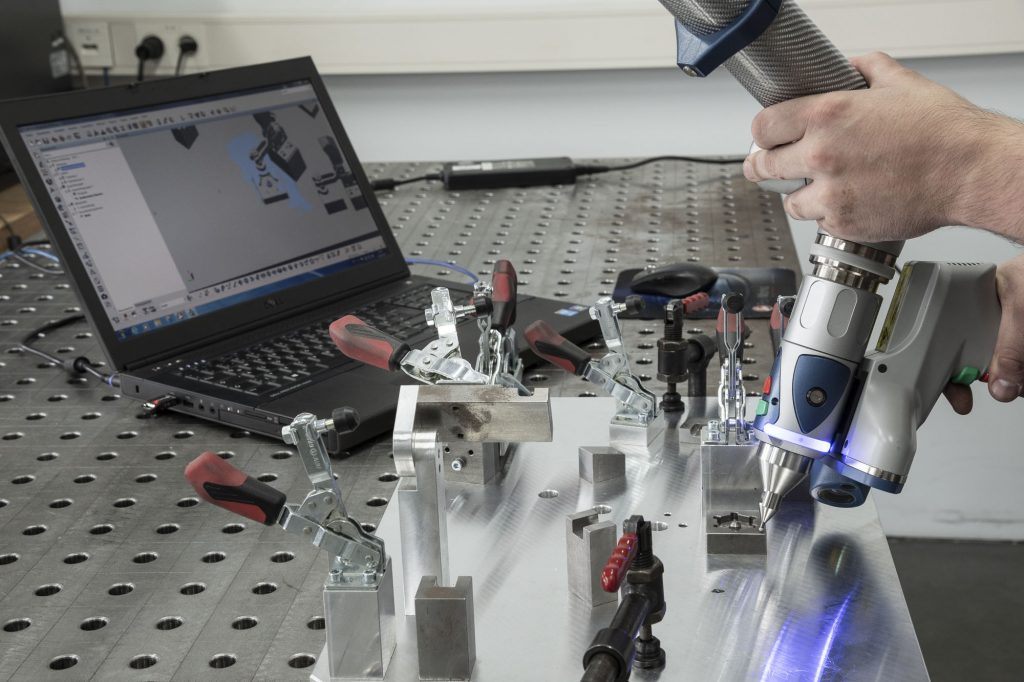

Der erste Schritt Richtung Qualität

Lötgerechte Bauteilmontage ist die Voraussetzungen für ein perfektes Lötergebnis. Bauteilabhängig wenden wir das effektivste und effizienteste Verfahren an.

Kosten- und Prozesssicherheit stellen wir für Klein- und Großserien sicher, indem wir gemeinsam mit unserem Kunden und unseren Werkzeug- sowie Vorrichtungspartnern die bestmögliche Lösung finden.

Ob manuelle Vormontage oder vollautomatisiert, Ihr Mehrwert ist für uns entscheidend.

Unsere Leistungen

Anwendungsbeispiele

- Löten

-

Unsere Kompetenz – Metalle ohne Aufschmelzen dauerhaft miteinander verbinden

Mit unserer langjährigen Erfahrung in der Wärmebehandlung zählen wir heute Kunden aus verschiedensten Branchen zu unserem Kundenstamm. Standard-, oder Serienfertigungen, Einzelteile oder komplexe Baugruppen – höchste Flexibilität ermöglicht dies:

- Kraftfahrzeugzulieferindustrie

- Metallbe- und -verarbeitende Industrie

- Maschinen- und Werkzeugbau

- Medizintechnik

- Armaturen- und Apparatebau

- Elektrotechnik

- Feinmechanik

- Möbelindustrie

- Sicherheits- und Verteidigungsindustrie

Unsere Leistungen

Anwendungsbeispiele

- Glühen

-

Mit Wärme Werkstoffeigenschaften ändern

Reinheit, die man nicht immer sieht: Das Aufheizen und anschließende Abkühlen von Metall unter Schutzgasatmosphäre führt zu chemisch blanken Werkstücken, frei von Zunder und Oxiden.

Das Rekristallisationsglühen kaltverformter Werkstücke ermöglicht ein weiteres Verformen. Denn anschließend ist der Werkstoff wieder spannungsarm und geschmeidig – damit erhöht sich die Standzeit des Umformwerkzeuges deutlich.

Die perfekte Basis für Ihren Umformprozess: Rekristallisationsglühen kaltverformter Werkstücke. Spannungsfrei und geschmeidig zur Schonung Ihrer Werkzeuge und Reduzierung von Mikrorissen.

Unsere Leistungen

Anwendungsbeispiele

- Bauteilmontage, -vorbereitung

-

Der erste Schritt Richtung Qualität

Lötgerechte Bauteilmontage ist die Voraussetzungen für ein perfektes Lötergebnis. Bauteilabhängig wenden wir das effektivste und effizienteste Verfahren an.

Kosten- und Prozesssicherheit stellen wir für Klein- und Großserien sicher, indem wir gemeinsam mit unserem Kunden und unseren Werkzeug- sowie Vorrichtungspartnern die bestmögliche Lösung finden.

Ob manuelle Vormontage oder vollautomatisiert, Ihr Mehrwert ist für uns entscheidend.

Unsere Leistungen

Anwendungsbeispiele

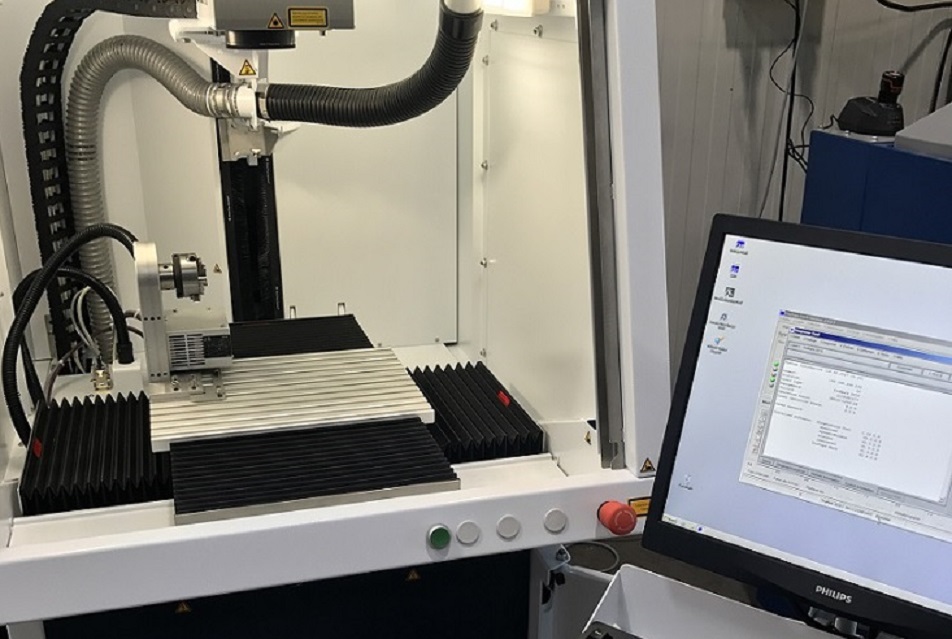

- Endprüfung,- bearbeitung

- QS / Labor

Übersicht

Die Leistungen der Löttechnik Burkhard auf einen Blick

Löten

Glühen

Bauteilmontage, -vorbereitung

Endprüfung, -bearbeitung

QS / Labor

Ihre Vorteile…

Qualität – Made in Bavaria

Bereits 1998 erhielten wir unsere erste Zertifizierung. Doch unser Ziel ist es nicht, der ISO-Norm zu genügen, sondern unsere eigenen, deutlich höheren Qualitätsstandards zu erfüllen.

Wir arbeiten auch nach den anspruchsvollen Standards von CQI-9. Diese Bewertungsgrößen hat die AIAG für Lieferanten in der Wärmebehandlung ausgearbeitet.

Vor diesem Hintergrund erfolgt auch die kontinuierliche innerbetriebliche Weiterbildung, um unsere Teams fachlich und qualitativ immer auf dem neuesten Stand zu halten.

Starten Sie mit uns Ihr Projekt

Sie liefern uns Ihre Anforderung – wir liefern Ihnen eine Lösung! Hinterlassen Sie uns einfach über nebenstehendes Formular Ihre Idee zu Ihrem gelöteten Wunsch-Produkt.

Mit unserer langjährigen Erfahrung erarbeiten wir gemeinsam mit Ihnen die beste Herangehensweise und eine passende Lösung.

Unser Team und unser leistungsfähiger Maschinenpark sind jeglicher Herausforderung gewachsen. Wir bieten Ihnen ein Ergebnis, das weit über den herkömmlichen Standards liegt.

Schreiben Sie uns jetzt an. Sie erhalten umgehend eine fachspezifische Beratung aus unserem Hause.